Melamine Faced Chipboard — A Practical Guide

In today’s world of interior design and home improvement, few materials have gained as much popularity as Melamine Faced Chipboard (MFC). Known for its balance of affordability, durability, and aesthetic flexibility, it has become a staple in both residential and commercial spaces. But what exactly makes it such a strong contender compared to other materials? Let’s take a closer look.

At its core, Melamine Faced Chipboard is a particleboard sheet that’s been laminated with melamine resin. The result is a sturdy panel that resists scratches, moisture, and everyday wear. What sets it apart is its ability to mimic the appearance of natural wood, stone, or even plain modern finishes without the cost or maintenance those materials usually demand.

For homeowners, the benefits are immediate. Imagine renovating your kitchen. Real wood cabinets are beautiful but come with a high price tag and the responsibility of upkeep. Melamine Faced Chipboard offers a sleek, uniform finish that’s resistant to stains and far easier to clean. Wipe with a damp cloth, and it looks as good as new — no special oils or varnishes required. Paired with decorative wall panels, it creates a cohesive and modern look that adds both texture and style to your space.

Design versatility is another huge plus. Manufacturers produce these boards in hundreds of colors, textures, and patterns. Whether you want a Scandinavian-inspired light oak look, a glossy minimalist white, or a deep walnut finish for a traditional touch, chances are there’s an option available. This makes it easy for designers and DIY enthusiasts alike to match furniture and fittings to broader interior styles.

Beyond aesthetics, practicality plays a big role. Melamine Faced Chipboard is relatively lightweight compared to solid wood, which makes it easier to transport and assemble. For furniture companies and contractors, this reduces costs and speeds up production. For the end user, it means more affordable prices without sacrificing durability.

Sustainability is another important factor today. Many chipboard products are made from recycled wood fibers, reducing the need for freshly harvested timber. Combined with modern eco-friendly production processes, MFC can be a more responsible choice than some alternatives.

Commercial spaces benefit as well. Offices, retail shops, and hotels all rely on materials that can withstand high traffic. Melamine Faced Chipboard delivers consistency: surfaces remain smooth, resistant to scratches, and easy to maintain even in busy environments. This makes it not just a budget-friendly choice but also a practical long-term investment.

Of course, like any material, it has limitations. MFC is not as strong as solid hardwood and can be vulnerable to heavy impacts if not handled carefully. But when used in the right applications — cabinets, wardrobes, shelving, or wall panels — it performs exceptionally well.

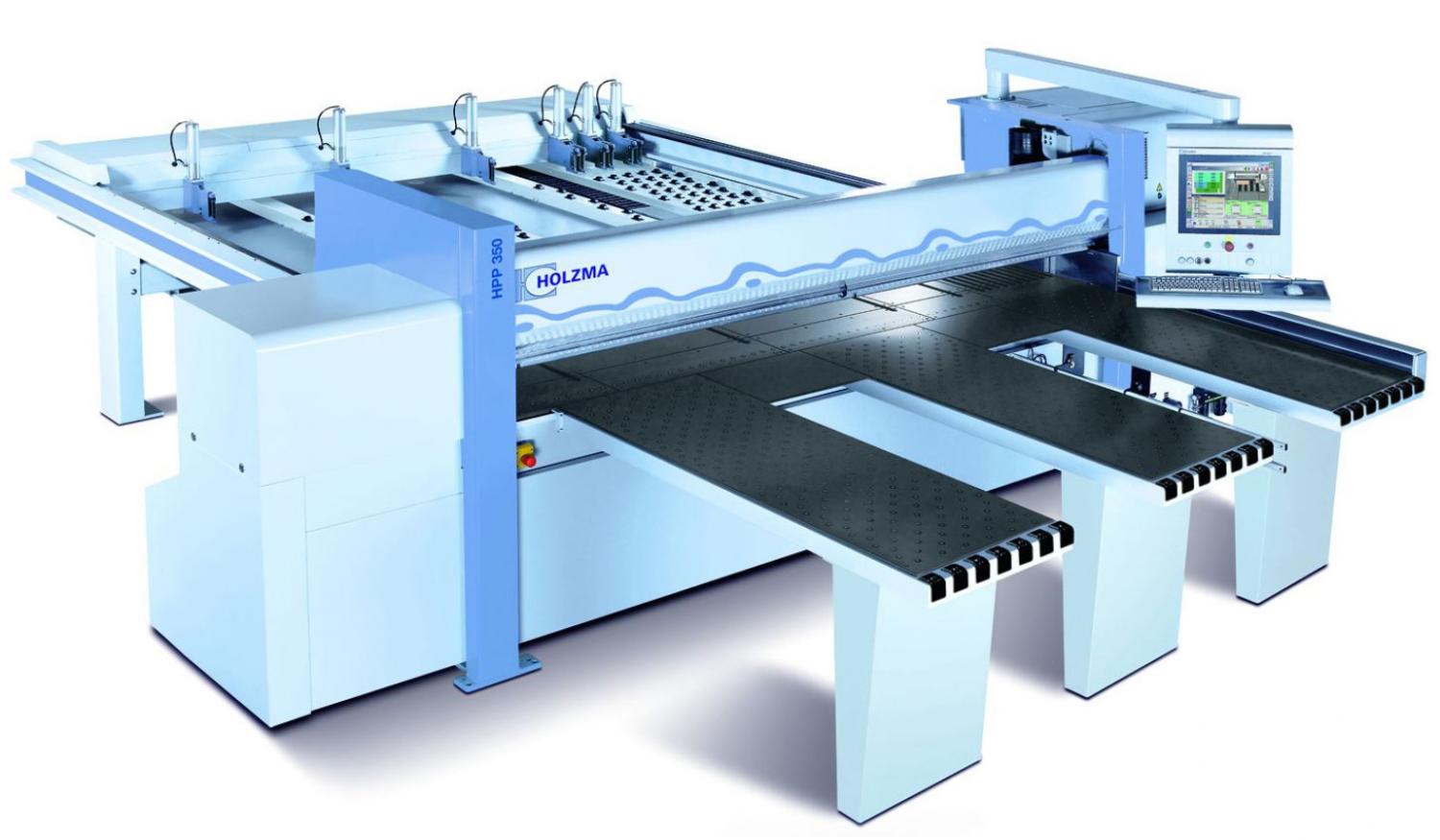

Another often overlooked aspect is customization. Thanks to modern cutting and edging technologies, Melamine Faced Chipboard can be tailored precisely to project needs. You can order it in varying thicknesses, shapes, and edge finishes, making it suitable for both standard furniture and bespoke designs.